Behind the scenes at Kim’s Chocolates, a Chamber of Commerce report.

Kim’s is growing fast while staying true to one idea: premium chocolate made with respect for people and planet. The Tienen factory runs 24/7. 180 colleagues, 35 nationalities, 15,000 tons of chocolate a year—and almost all of it exported worldwide.

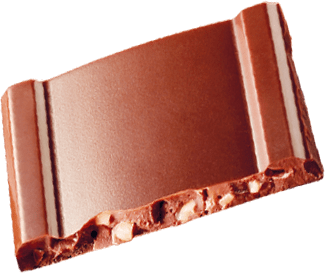

Why tablets lead the future

Younger consumers want simplicity, fun, inclusions. Tablets with nuts, caramel or fruit drive today’s growth.

Investing to stay ahead

Since 2018, we added three new production lines at the factory. A total investment of €45 million. The latest line is nearly fully automated. Volumes are huge and still rising.

Sustainability as a habit

Sustainability was part of the culture long before it became a buzzword. 4,000 solar panels since 2007. An in-house water treatment plant. And since 2015, sustainability has been anchored structurally through the Voka Sustainability Charter. That earned the company the titles SDG Pioneer and SDG Champion.

Looking forward in a challenging industry

Rising cocoa prices and climate pressure affect everyone. That’s why Kim’s is exploring alternatives like ChoViva: a cocoa alternative with a comparable taste experience and a much smaller environmental footprint. The goal stays simple: chocolate enjoyment with as little impact on our planet as possible.

Click: How a chocolate bar is made (8 steps) p. 34

1) liquid chocolate arrives

2) storage in heated silos

3) mould filling

4) visual and weight checks

5) packaging

6) automated logistics

7) in-house water purification

8) private label production for over 67 countries

Behind the scenes at Kim’s Chocolates, a Chamber of Commerce report.

Full report https://issuu.com/vokavzw/docs/ondernemers_vlaams-brabant_2025_10 (in Dutch only)

Link: https://www.voka.be/vlaams-brabant/publicaties/ondernemers-vlaams-brabant-2025-10